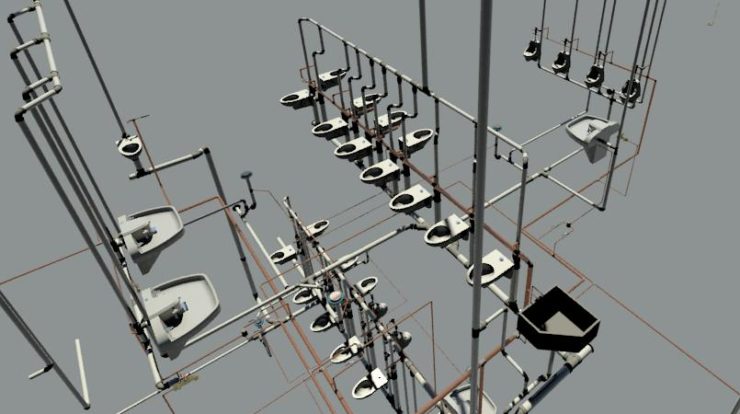

From reservoirs to pipes to cisterns and through all the bends in between, there lies an intricate maze behind the walls of our homes and offices, making water available with the turn of a tap, the push of a button and sometimes just a wave of the hand! But at times these design engineering marvels fail to bring us our promised aqua, sputtering and choking, creating what I like to refer to as plumbing nightmares.

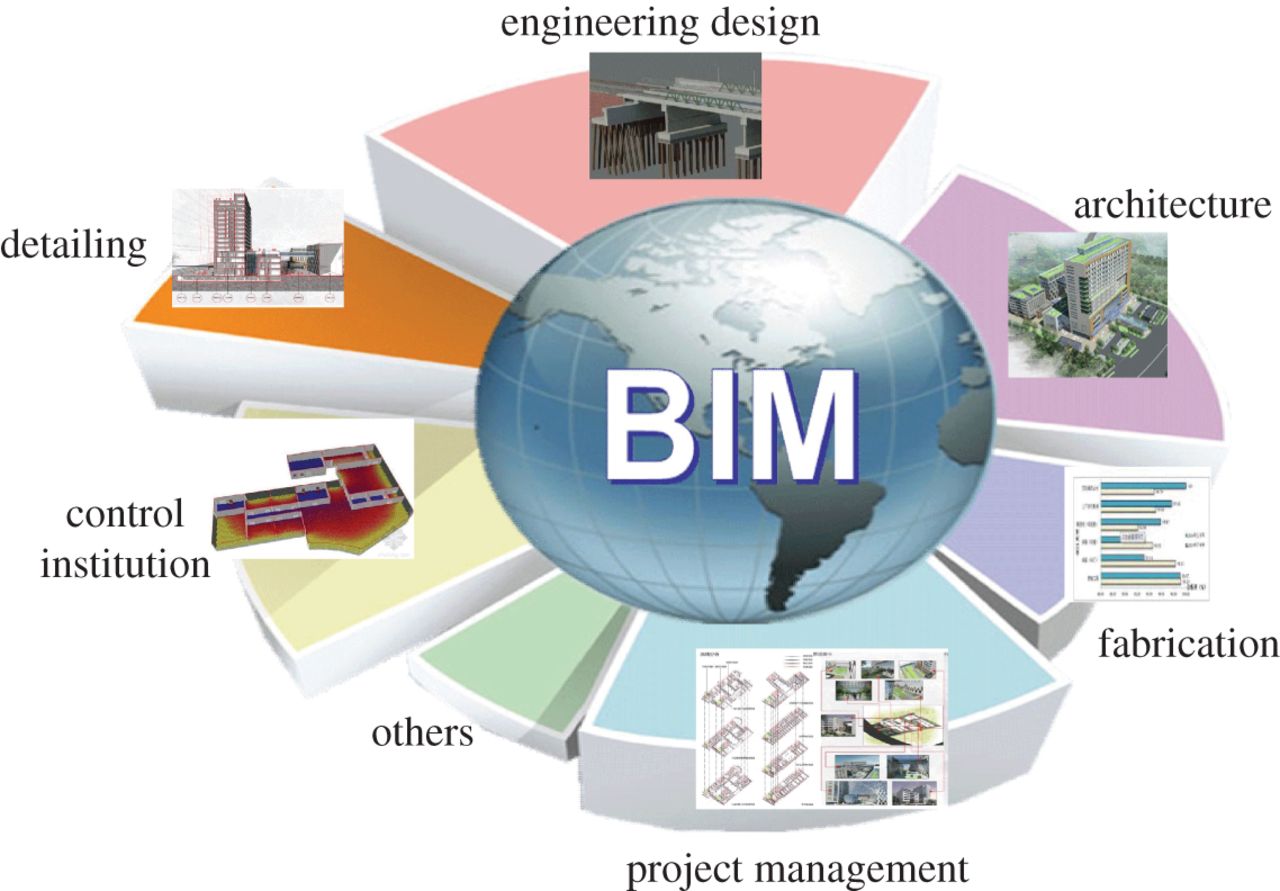

While 3D design software and BIM construction services have reduced these waterwork errors by a substantial amount, there still exists a large degree of human error and mechanical failure in plumbing today. Here is a look at some of the flawed design engineering systems that have wreaked havoc across the globe!

- Disproportionate Piping

Besides the obvious cost disparity of using incorrectly sized piping for a plumbing system, there are also some serious utilitarian flaws that these mismatched elements bring. Construction designers need to pay special attention to a diameter of the pipe being used.- Undersized pipes can cause blockages or even worse, backflow of waste and water.

- Oversized pipes, on the other hand, wastewater and have low water pressure.

- Pipe Angles

Geometry plays an important role in design engineering, and so does gravity! If pipes aren’t angled at the correct angle, waste can start accumulating and eventually cause major blockages. The gradient of the pipe should let water easily clear away any waste and residue, allowing gravity to pull it down and out. - Mixing Clean & Waste Water

As one of the worst mistakes a design engineer can make, connecting clean water-bearing pipes to wastewater ones, can result in major pollution, fines and legal action was taken against the offending party. - Maintain that drain!

In BIM implementations and other 3D building designs, these are often referred to as soft clashes. It is the absence of maintenance access to drainage and building structure. Drainage infrastructure is at most risk, due to an accumulation of waste and sometimes corrosive content. Regular maintenance of drainage systems should be a priority in any plumbing design.

We’ve taken a look at the bad of design engineering, it is now time to turn towards the good.

- Post Design Testing

Post completion testing of plumbing systems should be a given. To do so, first identify available water pressure in the project design. Following which, conduct thorough stress testing of the entire system by running water/ fluid of the same viscosity through it. - Consistency

Any good 3D design software will give you a complete 360 view of the plumbing schematic. Ensure pipe diameters are consistent throughout your design. Go over every bend and connector if need be, don’t miss a thing! - Accessibility

It’s not enough to simply design a system, design engineers need to keep accessibility and maintenance in mind. This is basic future proofing that can make your design more than just adequate, it can make it great!

Don’t let your customers fall victim to these plumbing nightmares. Create a solid design engineering process, with help from Technostruct. You can find us at https://www.technostruct.com/