The modern world is filled with leading-edge technology, and accessing a digital view of a real-life object is not beyond the reach of people. Hence, it is possible to imagine a technology that can create a digital equivalent of structures and their parts, such as walls, floors, machinery, etc.

Digital twins in construction are a revolutionary invention paving the way for efficient planning, construction, and project management. In this blog, let’s explore the role of digital twins, how they work, challenges, benefits, and examples of their implementation.

What is Digital Twin Technology?

This invention has enabled AEC professionals to access a tangible building or infrastructure’s interactive virtual representations. Advanced simulation models and real-time data from different sources such as BIM models, sensors, and other IoT devices, contribute to creating these virtual models.

Digital twins aid in the construction process, project lifecycle optimization, and improved decision-making. This tool offers an immersive experience of a structure’s critical data to the project stakeholders, fostering collaboration, boosting productivity, and mitigating issues, and RFIs.

How Does Digital Twins Technology Work?

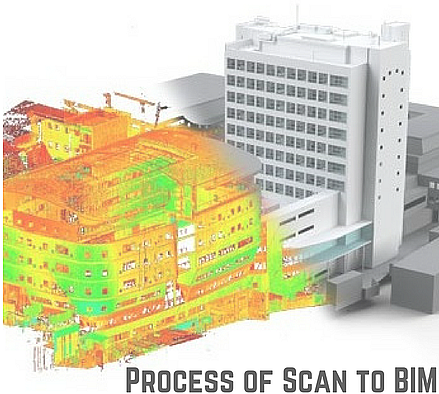

Incorporation of a broad range of technologies such as sensors, 3D laser scanners, cameras, and other Internet of Things (IoT) devices. Let’s discuss the 3 major stages involved in creating this system.

Capture

This process begins with capturing. You can gather data from the physical object, asset, or system. Internet of Things (IoT) devices and sensors are embedded in the physical asset.

These sensors collect different types of data in real time. It includes operational data (eg., temperature, pressure, humidity), performance metrics (eg., speed, load, cycle times), and environmental factors (eg., surrounding temperature, noise).

The data that is collected goes to a central system or cloud platform via communication tools such as Wi-Fi, Bluetooth, or other cellular networks.

Edit, Document, and Tag Building Assets

Blur and Tim are effective editing tools to enhance clarity and security in digital twins. This way, you can visualize physical spaces accurately in measurements and customized areas.

The next step is to place MatterTags and notes on the model to secure real-time information related to specific assets. This data is valuable in a handover package, which is given to an owner.

Share and Collaborate

Digital models allow you to share them with remote teams, which ensures you do not need to visit a site in person. As a result, you can experience better collaboration among team members. It also boosts environment-friendly business practices and lowers travel expenses.

Benefits of Digital Twins in Construction

Enhanced Visualization

Digital twins are the key to getting an immersive and data-rich visualization of a construction project. The integration of 3D models and real-time data facilitates stakeholders to get an in-depth view of the project.

Hence, they can gain better insights about the construction site, conduct design reviews, learn about issues, and make informed decisions.

Higher Collaboration

The inception of this technology has streamlined collaboration. Engineers, architects, contractors, and project managers get on the same page through this virtual platform that promises to foster communication.

Increased collaboration ensures all the personnel involved in the project are working with the same set of data. It can mitigate errors and boost project efficiency.

Cost Optimization

Optimization of a construction project’s costs is done by digital twins. Stakeholders can obtain data-rich insights and utilize them to effectively manage operations, find out the areas to reduce cost and curb the wastage of resources.

This method’s ability to simulate various scenarios contributes to efficient budget planning and ensures the financial viability of a project.

Real-time Monitoring

Twin digital models allow for live monitoring of activities occurring on a construction site. Integration of sensors and IoT devices into the project is used to process data to a digital twin, which provides the latest updates on the progress, potential issues, and resource utilization.

Harnessing this technology empowers the stakeholders to make proactive decisions, ensure the project is on schedule, and facilitate faster resolution of the issues.

Increased Safety

You can scale up safety on a project site through digital twins. This procedure is ideal for fetching live data from a construction site. For example, environmental conditions and movement of workers.

This advanced tool is equipped to send instant notifications and alerts, which pushes the team members to intervene immediately and prevent accidents.

Maintenance Prediction

Digital twins have the feature of predictive maintenance as they continuously monitor the condition of construction infrastructure and equipment. This modern system harnesses real-time data to predict the time of equipment’s breakdown.

It can prevent breakdowns and reduce downtime. This way, the machinery’s lifespan is increased and maintenance costs are reduced.

Challenges in Adoption of Digital Twins in Construction

Higher Costs

A construction firm, especially a medium-sized one can find implementing twin digital technology capital-intensive. Furthermore, integrating this system with existing ones and software requires resources and time, which is a challenge.

Lack of Training and Technical Knowledge

Technical proficiency is a must to implement this innovation. As a construction firm, you may have to spend money to train employees or hire new experts. It can hinder numerous companies from utilizing digital twins.

Data Overload

This technology processes a substantial amount of data, leaving the chances of information overload. You can also find it daunting to filter out the noise to get actionable insights.

Cybersecurity Threats

Digital twins heavily rely on data and communication, which makes them susceptible to cybersecurity attacks. Securing systems and information against cyberattacks is vital to ensure the credibility of this method. Hence, construction firms must invest in cybersecurity solutions to protect data integrity.

Issues Related to Scalability

The larger a project gets, the scalability of digital twins might become an issue. A construction company must grow for the accommodation of larger datasets and more detailed simulations to remain viable.

Resistance to Embrace New Technology

Individuals working in the construction sector have been reluctant to adopt new technology. This hesitation may arise due to a lack of awareness regarding the benefits of this system or being too accustomed to the traditional methods. Showcasing the usefulness of digital twins to the workforce can help break this barrier.

Real-world Examples of Digital Twins’ Implementation

The Shard, London, UK

The Shard is an iconic 95-story skyscraper decorating the skyline of London. Professionals integrated simulations of detailed architectural designs and comprehensive structures into the building’s digital twin. It aided in the design phase.

After the completion of construction, this asset continues to immensely contribute to monitoring a structure’s live performance.

One World Trade Center, New York City, USA

AEC professionals harnessed the potential of digital twins to complete the One World Trade Center. Engineers and architects were able to assess the structural integrity and predict environmental influences by simulating the building’s performance.

They also optimized various systems in the structure such as lighting and HVAC to ensure they perform optimally.

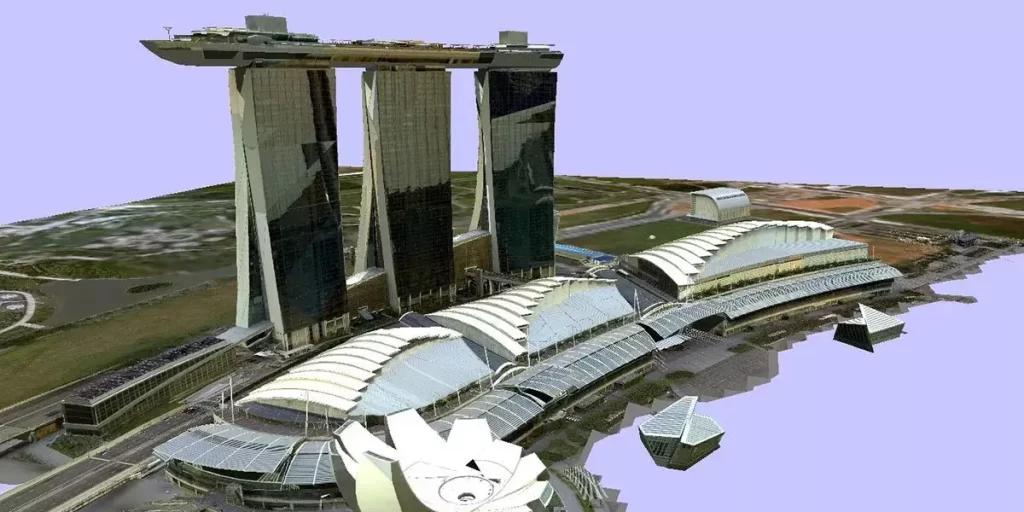

Virtual Singapore, Singapore

Virtual Singapore is a complete model that offers a glimpse of a reconstructed city. Incorporating digital twins in this project helps garner data in real-time as it includes drones, sensors, and other tools.

Additionally, this virtual model is poised to address environmental concerns and increase sustainability efforts. For example, stakeholders can make strategies to locate solar panels, considering the country’s vision to deploy at least two gigawatt-peak solar energy by 2030.

The Edge, Amsterdam, Netherlands

The Edge is renowned as one of the most sustainable buildings in the world. Data sources, energy consumption, and indoor climate parameters were integrated by digital twins to generate an intricate model of the building.

It enhanced precision in controlling heating, ventilation systems, and lighting to efficiently regulate energy usage and provide a suitable environment for occupants.

Heathrow Terminal 5, London, UK

Construction of Heathrow Terminal 5 began with the vision to create a state-of-the-art facility that would cater to millions of passengers annually. It was a grand project and having many stakeholders, detailed designs, and tight deadlines was obvious. This platform offered them an in-depth view of how they needed to execute the project.

Conclusion

Digital twins contribute to streamlining operations, mitigating risks, and improving the quality of work. This technology is causing a paradigm shift in the AEC industry and as per a study, the market for this virtual model will increase to $48.2 billion by 2026.

Professionals are leveraging this method to create models of smart cities. It plays a pivotal role in planning smart cities considering population growth and climate change. This platform enhances the capabilities of BIM by tracking, storing, and displaying complex data on the go to provide valuable and actionable information for simplified construction phases.

FAQs

Q1. What are BIM and digital twins?

Ans. Digital twins and BIM offer virtual glimpses of a structure. The main thing separating them is that BIM 3D models contribute to visualizing the design and construction of an asset. On the other hand, the latter allows virtual interaction with that asset.

Q2. What are the types of digital twins?

Ans. The four major types of this technology are component, system, product, and process.

Q3. What is the difference between IoT and digital twins?

Ans. The role of the Internet of Things (IoT) is to link devices and collect data from a physical environment to enable real-time monitoring and control. Whereas, the latter empowers professionals to create more precise simulations and do forecast analysis.