Construction, engineering, and many other projects require surveys. Professionals have long used traditional survey methods such as GPS receivers and total stations to gather data. However, the invention of 3D laser scanning technology has disrupted the AEC industry, inculcating speed, level of detail, and accuracy in operations.

This revolutionary technology streamlines design and planning for a construction project by offering complete and precise as-built site information. Laser scanning is characterized by speed and accuracy in capturing architectural, structural, and MEP features, concrete reinforcements, and underground utilities. It captures exact building dimensions, layouts, and locations to provide a site plan. Let’s learn more about it in this blog.

What is 3D Laser Scanning and How Does it Work?

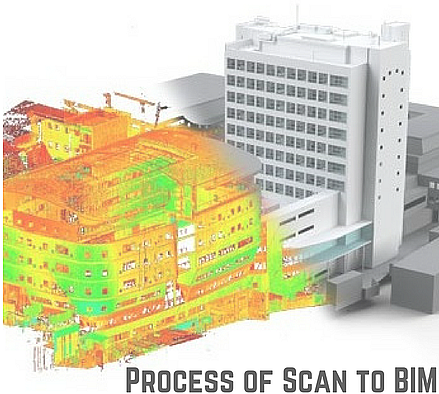

It is a technology that leverages laser beams to create intricate 3D images of environments, objects, or landscapes and measure distances to surfaces rapidly.

LiDAR (Light Detection and Ranging) technology aids 3D laser scanners in mapping millions of data points on a project site. In this process, rapid pulses of light are emitted, and they bounce off objects and reflect on the scanner’s sensor. 3D laser scanning technology measures the time each pulse travels to the object and back to calculate the distance between itself and the object. After that, it uses x, y, and z coordinates to convert all the data points into a pixel.

This tool covers many positions and angles to capture these points and compiles them into a point cloud. AEC professionals harness this point cloud to form a 3D as-built dataset of the site with more precision. This real-time data is easy to analyze and convert into intricate 3D BIM models and 2D CAD drawings.

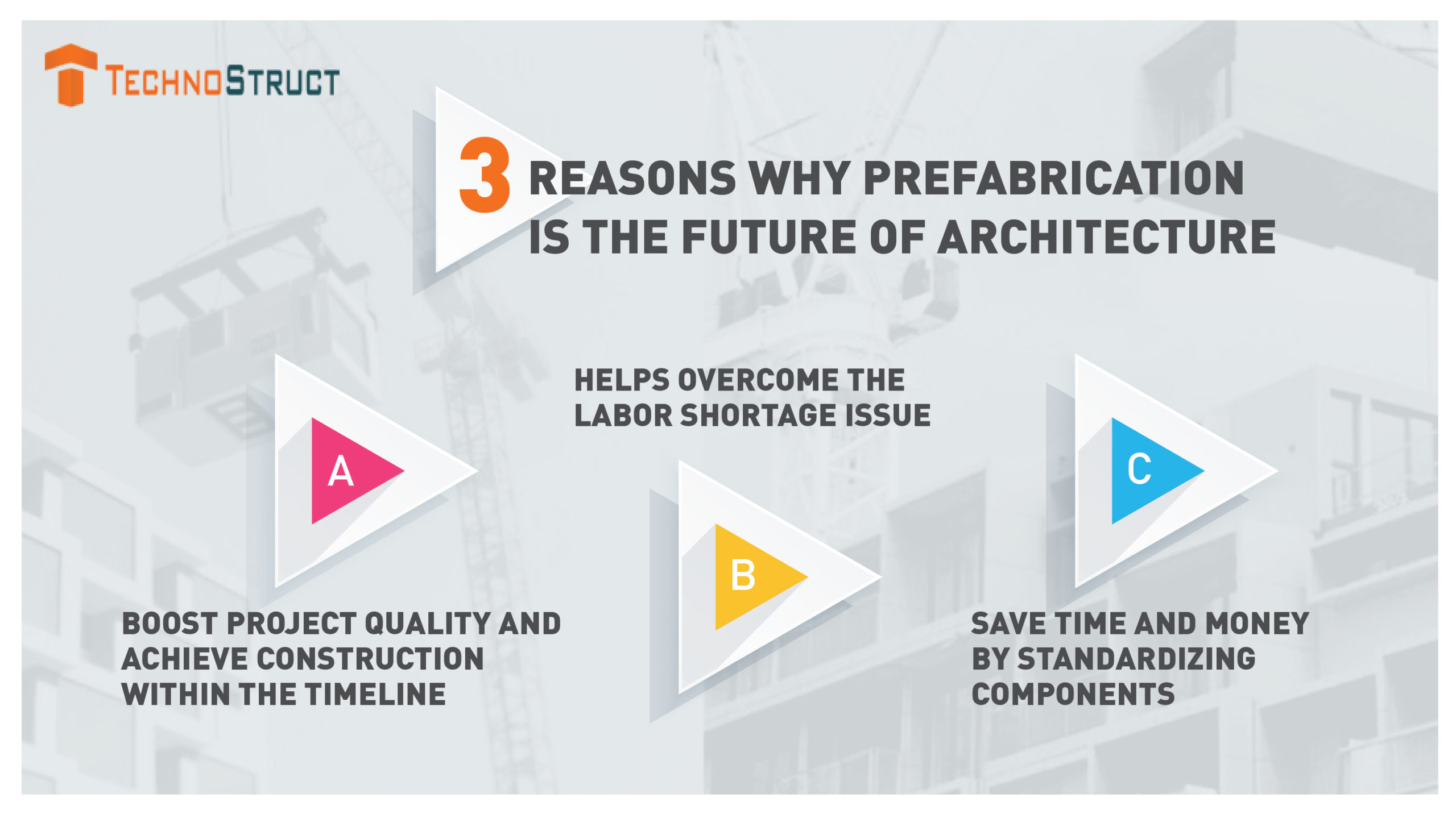

Facility visualization and as-built documentation become cost-effective and precise using 3D laser scanning. Integrating this tool accelerates engineering, design, and construction processes and mitigates costly errors. 3D laser scanners simplify access to in-depth information essential for design planning, renovation, prefabrication, construction, asset management, and facility modifications.

Benefits of 3D Laser Scanning

Precise Visualization and Documentation

The invention of this leading-edge technology has made professionals realize the inadequacies traditional methods show in documenting complicated structures. This system captures millions of data points every second to generate a detailed and precise model of the built environment. This documentation contributes to well-informed decision-making throughout a project’s lifetime.

Improved Planning and Design

3D laser scanning plays a vital role in improving planning and design. It facilitates engineers, architects, and designers to find issues in the design, conflicts, and spatial limitations before the construction process starts. As a result, construction operations run smoothly with a lower need for costly design modifications and higher project efficiency.

Effective Surveying and Data Collection

Using traditional surveying techniques requires more intensive resources and time. This system speeds up the process of recording current conditions. It covers difficult-to-reach places and quickly captures a substantial amount of data. This results in cost savings as project duration is shortened and output is improved.

As-Built Verification

Comparing the as-designed model with as-built circumstances is a crucial aspect of quality control. AEC professionals maximize the potential of terrestrial 3D laser scanning to confirm the accuracy of alignment of the built structure with the intended design. This verification process ensures the project adheres to rules, specifications, and regulations.

Conflict Detection and Resolution

Terrestrial 3D laser scanning can detect collisions and conflicts among various building systems, such as mechanical, electrical, and plumbing (MEP). If the conflicts are not resolved, issues like rework, delays, and overspending can occur. Using a digital model to detect and resolve such issues can aid the project teams in mitigating risks and optimizing operations.

Data-Driven Maintenance and Facilities Management

The 3D laser scanner’s role goes beyond construction and assists in maintenance and facilities management. Having access to the virtual representation of a building facilitates property managers to conduct condition evaluations, schedule maintenance activities, and oversee revisions. This way, they can optimize operational effectiveness and the lifespan of the structure can increase.

Challenges in 3D Laser Scanning

High Complexity in Geometries and Occlusions

Professionals face difficulties in scanning objects with complex geometries. This technology can gather incomplete data if there are in-depth details, deep recesses, and occluded areas (the things that the scanner’s line of sight cannot reach).

The scanning process can take lots of time and effort as the teams take multiple scans from different angles to capture all the details. Additionally, it is a difficult task to merge these scans into a cohesive model. Significant manual intervention and high-end software algorithms are a must to boost comprehensiveness and precision.

Material Properties and Surface Reflectivity

Another challenge in the 3D laser scanning process is to deal with various surface properties. There is a possibility of incomplete or inaccurate data if the surface is very shiny or reflective as the laser beam can scatter due to it. Also, laser refracts or passes through transparent surfaces such as water or glass, which can cause issues in the scanned data.

Operators often use coatings or matte sprays to reduce such problems. However, it can consume lots of time and may not be feasible for every site.

Conditions Related to the Environment

The quality of 3D laser scans depends on environmental factors. Different outdoor conditions like fog, rain, and direct sunlight can make the scans challenging as they can affect the performance of the laser. The accuracy of the scan can also be impacted by dust and airborne particles.

Calibration issues can arise if the equipment contract or thermal expansion occurs due to fluctuating temperatures.

Data Processing and Volume

Scanning an area or object at high resolutions causes the generation of a large amount of data. It is necessary to install high-performance computers and advanced software to manage, store, and process this information. It can be costly.

Additionally, extensive post-processing, aligning multiple scans, noise reduction, and creating surfaces or meshes are essential to convert raw scan data into usable models. Expertise in handling 3D laser scanning is required and this process can also be time-consuming.

Access to Certain Areas and Mobility

It is a complex task to scan certain areas such as heritage buildings and industrial plants. Placing scanners in the right locations is crucial to capture various details. A confined or hazardous environment may make it challenging.

Although, the industry has access to portable and handheld scanners, however, they might not ensure the accuracy and range of stationary ones. Hence, consider mobility with high-quality data requirements.

Training Workforce and Cost

Hands-on experience in 3D laser scanning is vital for professionals to leverage it. In-depth technical knowledge of the equipment, scanning process, and post-processing makes the operators use it confidently. Providing training to the workforce can be costly.

Furthermore, small firms and individual practitioners can find the cost of this technology massive. They may have to invest heavily in top-notch scanners and software for data processing and analysis.

Combining with Other Technologies

It is challenging to integrate these scanners’ data with other construction technologies like BIM (Building Information Modeling), CAD (Computer-Aided Design), and GIS (Geographic Information Systems).

Various file formats and requirements for maintaining precision in alignment and transformation between different coordinates can cause data compatibility issues.

How to Implement 3D Laser Scanning?

Know the Right Time to Buy or Rent

Purchasing this system can be costly. It is ideal to rent 3D laser scanners while planning to implement them in a project for the first time. Invest in this innovation, once the return on investment is clear.

Begin Early

Implementing this technology at the start of a project ensures the highest level of precision. Hence, it should be introduced early in the project to maximize its potential.

Integrate with Other Technologies

Combining 3D laser scanning with other technologies can boost efficiency in a construction project. Thus, integrate it with other systems such as BIM to create an in-depth and comprehensive model.

Final Thoughts

3D laser scanning technology has caused a paradigm shift in the construction industry. This sector is harnessing these scanners to promote accuracy and clash detection, organize documentation, and enhance quality control as well as facility management.

The evolving construction industry should embrace this method to foster accuracy and innovation in operations.

FAQs

Q 1: What is a 3D laser scanner application?

Ans: This technique captures the as-built conditions of a plant with accuracy. It creates a 2D CAD drawing or 3D BIM model to document the existing P&ID tools, flow of control, and piping. Its uses are in modification, maintenance, and referencing the process plant.

Q 2: What affects the scanning speed of a 3D scanner?

Ans: The size of an object affects the scanning speed of a 3D scanner. It takes longer to scan a large object, than a small one due to 3D laser scanners having limited range.

Q 3: Are 3D laser scanners safe?

Ans: These scanners are not hazardous for a structure or person and can be portable.