Even minor errors in planning and operations can be costly in the construction sphere. Hence, laying a strong foundation for a construction project is paramount. Here enters rebar detailing, which is at the core of a powerful and durable structure.

AEC professionals must not overlook rebar drawings, as a slight mistake in fitting steel elements can lead to building a leaning tower. Leveraging these drawings to create an in-depth visual representation of the size, length, shape, and placement of rebars propels the workforce to place steel material in the structure. This blog discusses the same in detail.

What is Rebar Detailing or Rebar Shop Drawings?

This process involves creating intricate drawings and schedules to ensure precision in reinforcing bar placement to reinforce a concrete structure. Rebar fabricators, rebar detailers, and structural engineers create rebar shop drawings.

It aids them in churning out reinforcing bar bending schedules and creating precise detailed drawings. Precise rebar drawings facilitate the reinforcement process and lead to error-free structure delivery.

Essential Information Rebar Detailing or Rebar Shop Drawings Offer

Rebar shop drawings provide key information about properly installing reinforcing steel in a project. Let’s examine some of its critical points below.

Rebar Schedule: A rebar schedule comprises all the sizes, shapes, lengths, and quantities of the rebars essential for a project. It summarizes the details of the rebars and ensures that all the required materials are available.

Rebar Details: These refer to the in-depth drawings of every rebar assembly. They show the type, size, and spacing of bars. Additionally, information about hooks, bends, and special details is easily accessible. Rebar details are vital for showing the ideal way to place a rebar within the structure to obtain optimal structural strength and integrity.

Bar Bending Schedule (BBS): This document lists the rebars essential for a project and shows how to fit them into their designated spots precisely. Thus, the rebar can be cut and bent easily.

Location and Spacing: Professionals use these drawings to highlight the exact spacing and placement of rebar in the concrete elements. They prioritize the correct placement of reinforced steel within the structure and ensure the required structural support.

Clear Cover: These specifications define the distance between the nearest reinforcing bar and the outer concrete surface. They maintain the rebar’s effectiveness and prevent corrosion.

Development and Lap Lengths: Utilizing this data is critical to learn how and where to lap or splice the rebar. It fosters strength and continuity.

Material Specifications: This section in rebar detailing provides various material specifications, which include the grade and type of reinforcing steel that will be used in the project. Hence, professionals can use effective materials for better performance.

Anchorage Details: Rebar anchoring into footings, foundations, or other structural elements is guided by these details. It is crucial for resisting forces and pullout prevention. Other essential anchoring information included in this section is hooks, ties, seismic detailing, etc.

Structural Notes: These notes offer insights into rebar placement, structural design, and construction. It works as a guide for the contractors to offer particular instructions to follow in the construction process.

Benefits of Rebar Detailing

Cost-effectiveness

Rebar detailing equips the engineers and contractors to optimize the steel distribution and placement, which leads them to lower installation costs. Moreover, it contributes to waste and error reduction and efficient management of resources.

Enhanced Structural Integrity and Safety

Structural integrity and safety of a structure are maintained by accuracy in the rebar detailing. Implementing this method is the first step towards the correct placement of reinforcement bars and offers higher support and strength to the upcoming building.

Better Quality of Construction

AEC professionals can improve construction quality using rebar drawings as they foster accuracy in the placement of reinforcing steel within a concrete structure. They emphasize ensuring the adherence of rebar assemblies to design specifications. It boosts the project’s structural integrity.

Compliance with Design Code

Large engineering projects benefit from complying with building standards and codes such as ASTM, CRSI, and ACI. The creation of rebar shop drawings is the ideal way to move towards ensuring that reinforcing components and bars adhere to regulatory guidelines. Hence, the safety and durability of a building is improved.

Improved Collaboration

These drawings ease project management and promote collaboration among stakeholders. They can provide clear instructions on joint details and strengthen concrete elements to organize the workflow. It propels the project toward timely completion.

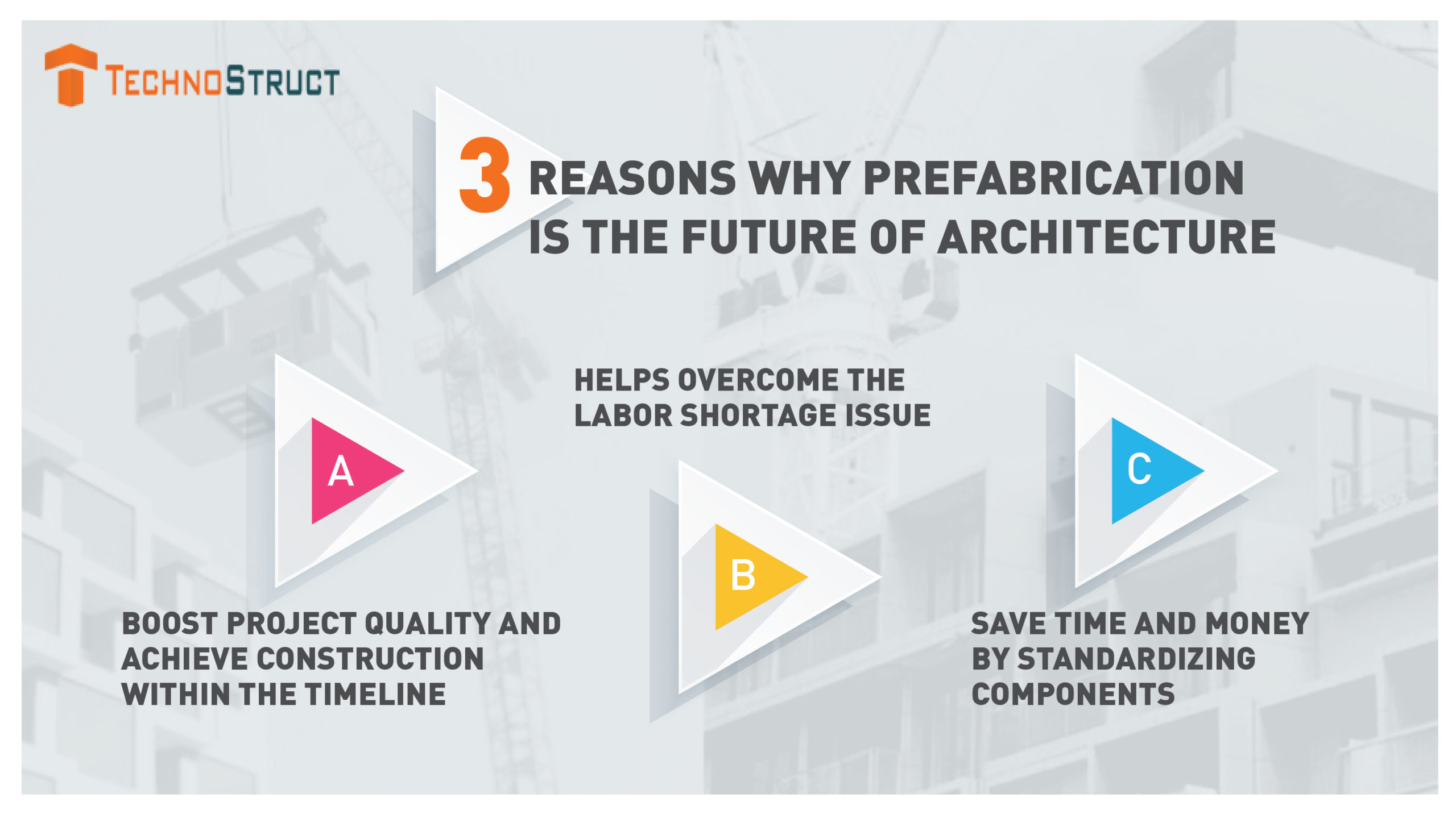

Facilitates Prefabrication

Off-site prefabrication of components can be done easily using rebar detailing. It improves productivity and reduces the requirement for on-site labor. Professionals can minimize errors, site safety risks, and construction as they can identify potential conflicts at the design stage.

As-Built Documentation

The creation of precise as-built documentation gets easier with rebar drawing. These records play a significant role in the regular repairs and maintenance of the buildings.

Challenges in Rebar Detailing

Steel Bars and Neighboring Structures’ Clash

The clash among steel bars and adjacent structural elements may not be easy to detect in 2D representations. 2D drawings’ inability to fully present spatial relationships can cause this thing to occur. Also, it can occur due to the use of various drawings for different reinforcements without proper alignment.

BIM provides a complete 3D representation of the entire rebar model to resolve this issue. A unified 3D model shows all the strengthening components, leading to early interferences and collision detection. This way, professionals can resolve the conflicts before the construction begins and save costs.

Interpreting Intricate Structural Designs

A firm grasp of the key engineering principles is necessary to interpret complex structural designs. It is also required to assess in-depth 3D models or blueprints to break down the structure into its fundamental parts. Analysis of load distribution and transfer through the structure is critical, along with relevant building codes and standards review to boost safety.

Interpreting structural designs can become easier with guidance from a seasoned professional and through the use of structural analysis software. Overall design comprehension further increases by considering the construction methods and design context and recognizing repetitive patterns.

High Costs Due to Errors in Steel Bar Sizing

A clearer view of the specifications of every steel bar through 3D modeling tools can aid in mitigating this issue. 3D models facilitate this as they mark steel bars differently. They color code steel bars and size. The identification and correction of errors at the design stage are simplified with this realistic rendering. It paves the way for correctly specifying all components before fabrication begins.

Cross-planting Steel Bars at Joints

2D drawings may not illustrate steel bars’ placement with precision, especially at joints. It leads to extra reinforcement work and confusion, which increases costs.

3D design uses design intent to generate preliminary models for assisting in identifying overlaps and conflicts early. This way, high-congestion areas can be detected and adjusted before construction starts.

Design and Specification Change Management

This project systematically documents and assesses proposed changes for their potential effects on scope, schedule, and budget. All associated documents and communicating those updates to the team members and contractors is crucial.

Hence, meticulously implementing changes with updated communications aids in keeping the project in line and addressing the changes easily.

Conclusion

Rebar detailing is paramount for ensuring the safety and durability of concrete structures. Seasoned rebar detailers and engineers can provide a compelling structural design for strengthening bars that adhere to specifications, safety, and quality requirements.

This process can define whole elemental cohesion, value, and scalability. Hence, practice rebar detailing to build robust and durable structures.

FAQs

Q1. Does rebar break easily?

Ans. Placing rebar in concrete makes a composite material. This way, rebar offers protection from tensile stress and concrete safeguards from compressive stress. It is a powerful composite material. The rebar covered by concrete has a double breaking point compared to concrete without rebar.

Concrete that does not consist of rebar is brittle. Hence, the increasing pressure on concrete will break the structure. However, concrete, which has rebar, is considered ductile.

Q2. What is the role of a rebar detailer?

Ans. Here are the essential tasks a rebar detailer performs:

- Blueprints decoding.

- Creating complete placement drawings.

- Collaboration with stakeholders.

- Optimization and resolving problems.

- Precision and quality assurance.

- Creating complete barlists for fabrication.

Q3. What are the tools used in rebar detailing?

Ans. The top rebar detailing software are mentioned below:

CADS RC.

Autodesk Revit.

Bentley ProStructures.

Tekla Structures.

Allplan Engineering.

RGS Rebar.