Whether seen in nature or by human design, symmetry has always carried an aesthetic beauty that artists and designers have tried to capture in their work. In the Architecture, Engineering, and Construction (AEC) industry, symmetry has always been a staple. However, recent correlations between symmetry and repetition in the AEC sector, have completely revolutionized the effectiveness of Revit design.

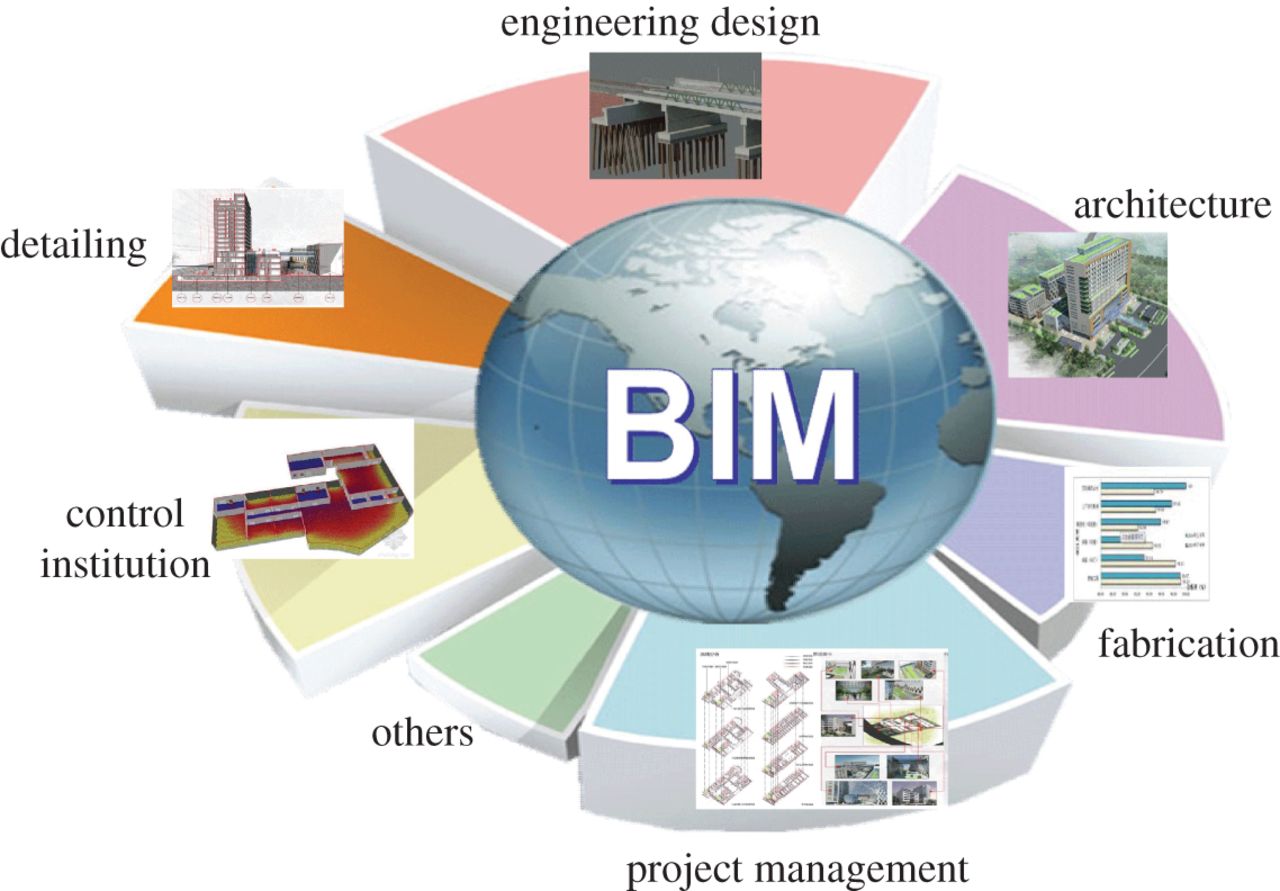

It is important to note that BIM designs incorporate a wide range of disciplines, and amongst these, engineering and architectural disciplines both show regularly repeating patterns in design. So as we progress further, keep in mind repetitive elements can be in reference to both fields.

Revit Groups

An extremely useful Revit design feature is the ‘group’ functionality. This is what makes repetition and prefabrication possible. Here’s how it work:

- First, a set of data points is collated or grouped together.

- Then, these set of group data points is consolidated into group libraries, which can be called in their entirety to recreate structures.

Before these repetitive structures can be integrated, BIM designs must create connecting parts or ‘extensions’ to provide seamless connectivity.

We’ve seen how one can implement repetitive BIM designs in Revit, let us now take a look at what benefits this poses for your BIM implementation.

Aesthetic

Repetition is synonymous with symmetric design. Pleasing to the eye and easy to implement, these aesthetically pleasing structures have been seen around the globe throughout history. In modern architecture, these symmetric designs are incorporate in tandem with minimalistic styles to create awe-inspiring masterpieces.

Variations

Once a base Revit design has been created using group libraries, it can be modified to fit a variety of purposes. Think of the BIM design as moldable clay, it can be modified and shaped to fit any function.

Speed

The biggest advantage of using repetitive elements in BIM implementations is the speed with which designs can be created. Consider a 3D building design that makes use of three distinct repetitive elements a grand total of ten times each. Instead of designing thirty new rooms and structures from scratch, a design engineer could effectively design the three elements, with extensions and connect them as many times as desired!

And there’s more! By creating a single base element or module to work off, the BIM designer doesn’t have to worry about entering information such as parameters and values repeatedly for every single structure!

Estimates

By determining how many repetitive modules are going to be used in the Revit design, BIM service providers can accurately determine exact cost estimates, simply multiplying the cost of one such element by the total number of units required.

Collaboration

Creating base modules or ‘shells’ allow multiple teams to work in perfect unison, each party adding different elements and functionality to the Revit design, finally saving it as a separate file. It can allow construction designers and engineers to work in parallel on completely isolated structures, but by using the same shell!

Prefabrication

Before the BIM design is even finished, repetitive elements can be finalized and sent off to manufacturers for fabrication. These prefabricated elements can be created side by side with the designing process and directly implemented into the final schematic. Not only is this a huge boost to productivity, but also a great cost saving method.

Auditing

Armed with a checklist that is similar across every module in the BIM implementation, audit officers can efficiently conduct their checks in minimal time and with great accuracy.

`Who knew the amazing ways a repetitive element could superpower your Revit design. Find out more about BIM implementations and use of modern evolving technology with a globally leading BIM service provider, Technostruct. Find us here: https://www.technostruct.com/